Plastic is becoming probably the most typical materials in the production sector. It is actually light in weight, long lasting, and will be molded into any form or design. Just about the most popular ways of molding plastic-type is rotational molding. In today’s article, we shall be discussing the particulars of rotational molding and just how it can be used to create high quality plastics.

Precisely what is Rotational Molding?

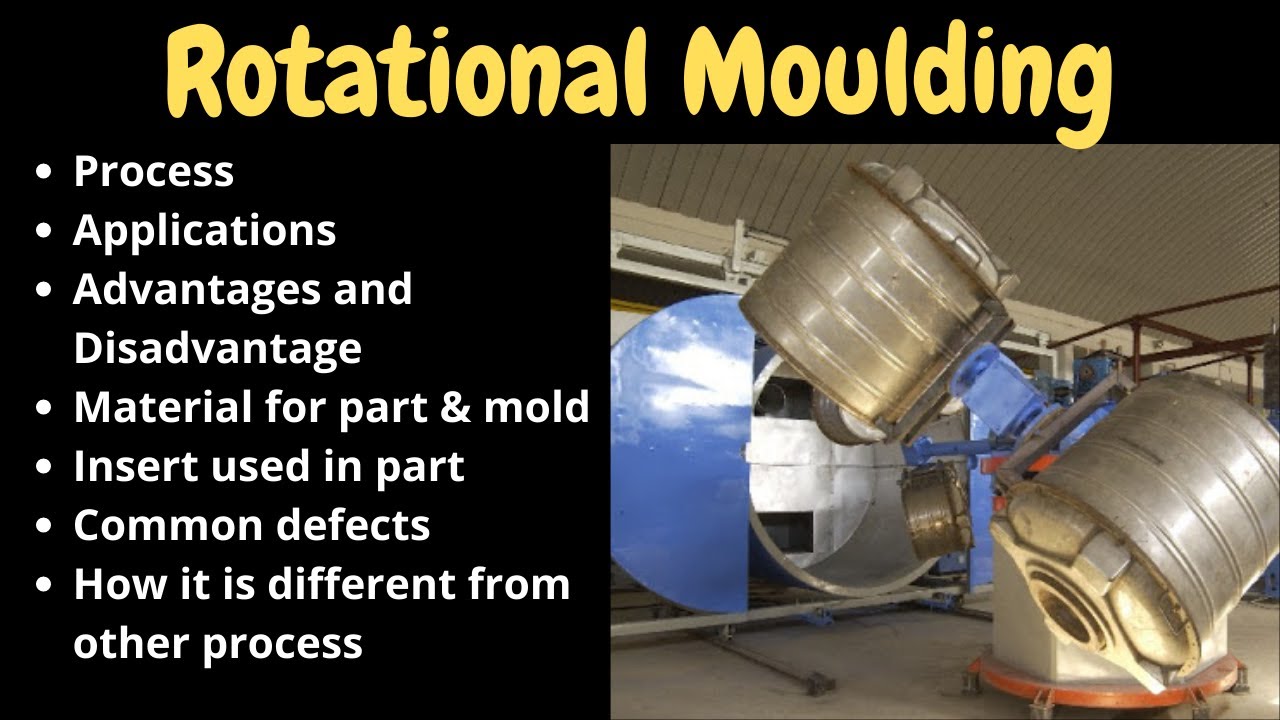

Plastics Rotomolding, also known as roto-molding, is actually a manufacturing method employed to make hollow plastic-type merchandise. The method entails heating a plastic material substance within a mold, which happens to be then rotated in several guidelines to disperse the dissolved plastic-type material evenly throughout the inside the mildew. When cooled, the fungus is established, uncovering the finished item.

Benefits of Rotational Molding

There are various advantages to employing rotational molding. The most significant benefits is it enables the roll-out of intricate shapes and fashoins. The method also produces items that are standard in fullness, which makes them more powerful and less susceptible to disorders. Additionally, the method employs significantly less material than other strategies for molding, rendering it more inexpensive.

Resources Used in Rotational Molding

A wide range of materials may be used in rotational molding, including polyethylene, polypropylene, and Pvc material. These materials are known for their durability and potential to deal with effect, causing them to be suitable for a number of programs. Additionally, these components could be compounded with preservatives for example UV stabilizers, flames retardants, and influence modifiers to further improve their overall performance qualities.

Uses of Rotational Molding

Rotational molding is commonly used in many different sectors, which include automotive, health care, and customer products. Some common uses of rotational molding consist of gasoline tanks, play ground products, storage containers, and kayaks. In addition, the procedure is widely used to generate custom made goods for area of expertise programs.

Quality Handle in Rotational Molding

To ensure that high quality plastic-type merchandise is generated, rotational molding requires tough good quality manage actions. These measures consist of tracking the temp and timing in the molding process, tests the thickness of the product or service to make certain consistency, and inspecting the finished product or service for almost any flaws or imperfections.

Simply speaking:

Rotational molding is becoming a necessary process in the plastic-type material producing industry, due to its fine quality and price-efficiency. It is traditionally used in several sectors, and the procedure is continuing to develop in such a way that make it more effective and successful. With top quality management steps in position, rotational molding will continue to reinvent the plastics business for years to come.